performance

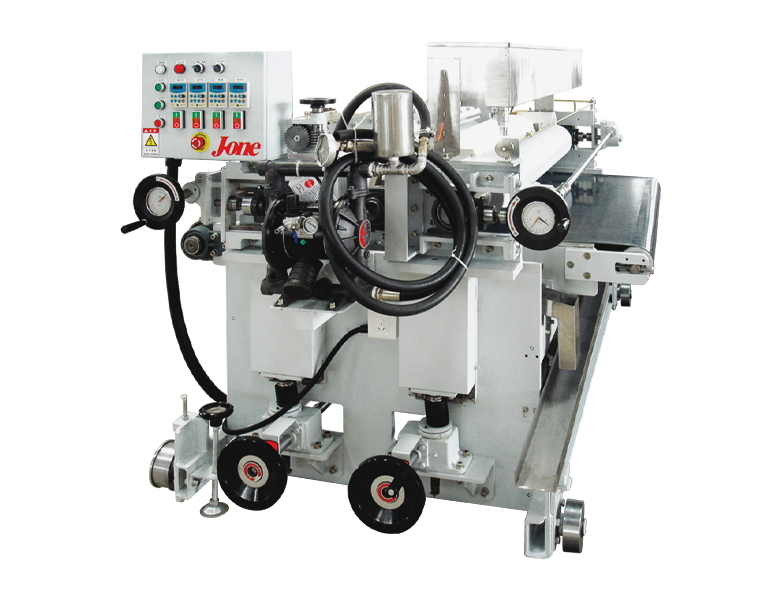

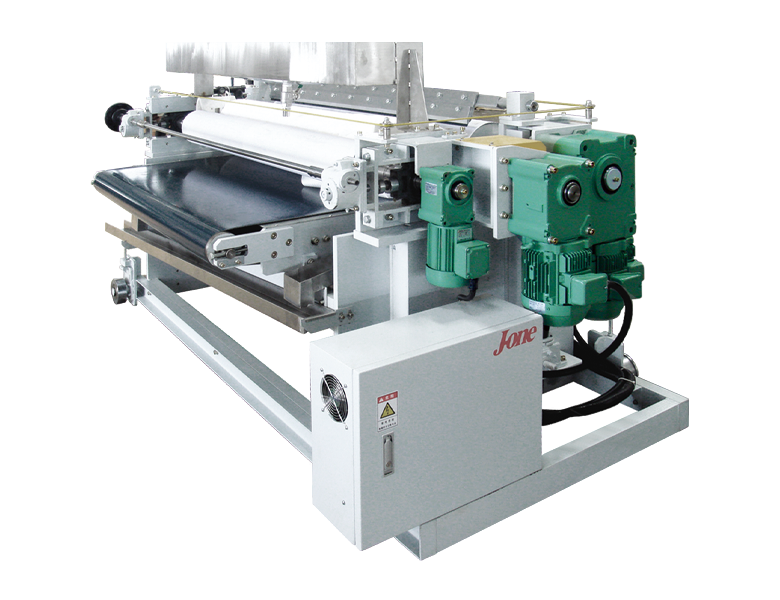

J-One series products of hot wind dry oven are complete design from Japanese project and technology. Dry hot source could choose from steam, electricity heat or combustion machine according to customer’s need. Its reasonable structure, cultured materials, advanced technology on sealed heat preservation system and dampness prevention system contribute to remarkable impacts on effective use of heat power and energy saving. Adjustment device of wind speed and temperature can set wind speed and temperature in section, which accurate adjustment of above two can be achieved. Unique design of tube style muzzle can eject hot wind to dry workpiece rapidly by 25m/s evenly. This assures the dry effect; especially through steam heating mode which cost reduces to the lowest.

The gush style dryer used mainly on PU、PE、NC、Fluorine Carbon Paint、Water Paint and other kinds of dope, which accelerate the drying speed of smearing. It is suitable for pipelining and continuous production style. The workpiece will enter the dryer from one end by set speed after smearing, as for the temperature and wind speed has been set in different section according to dope character, it will out from other end after certain time and reach to idealistic dry effect (all dry or surface dry). The workpiece can enter into next procedure directly to further spraying, polishing or packing.

86 135 6065 7918

86 135 6065 7918